Nationwide Mining Corporation (NMC) is an independent manufacturer and supplier wear products for the mining, mineral processing & manufacturing industries among others.

Located in Melbourne, Brisbane, and Perth, we specialize in top-quality wear products and wear components, reliable solutions for wear issues, optimisation of process equipment and applied engineering solutions

From design to manufacturing, as specialist engineers of wear resistant products, we can help you with your mining, quarry, and civil industry needs.

A full range of industry leading wear products is available in stock for purchase. We are also able to meet your custom requirement with a team of specialised Engineers on site

Application Of Our Wear Products

- Impact Wall Liners

- Jaw Crushers

- Chute Linings

- Crusher Chutes

- Tripper Chutes

- Flop Gates

- Bucket Liners

- Grizzly Bars

- Lip Protectors

- Screen Plates

- Bucket Liners

- Distribution Plates

- Bucket Wheel Protection

- Conveyor Transfer Points

- Chutes Apron Feeder

- Liners Loading Pocket

- Liners Splitter/Divider

- Floor Liners

- Loaders

- Wear Aprons

- Knife Inserts

- Dump Hoppers

- Crusher Hoppers

- Vibratory Feeders

- Rock Box Edges

- Surge Bin Liners

- Rock Box Liners

- Skip Liners

- Trough Liners

- Concentration Bins Buckets

- Transition Pieces Coal Transfer

- Shovels

- Bolt Protectors

- Truck Bed Liners

- Plates Hammer Mill

- Hopper Edges

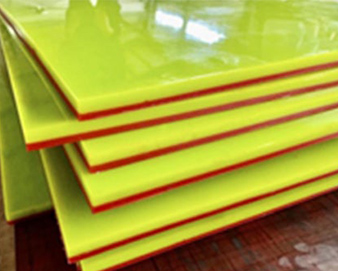

Polyurethane

Polyurethane’s unique ability to resist impingement wear, and improve noise abatement and vibration-dampening characteristics, make it an ideal solution for demanding applications and coarse environments in the mining industry. Our ultra-abrasion-resistant compounds have been proven to reduce down time and protect metal components in a number of aggregate applications and often significantly outlasting competitive products. We can also offer custom moulded solutions with a strong emphasis on product performance and timely deliveries

Rubber

NMC’s Rubber products are manufactured with the highest quality equipment to ensure we exceed our client’s expectations every time. The mining industry relies on many rubber components for their wear applications. These rubber products and components must be designed to withstand plenty of impact and abrasion in demanding environments.

Ceramics

Our ceramic range CeraTuff has three different alumina composition products (92%, 95% and ZTA) to suit the various mining applications.

Ceramic wear liners range include composite ceramic liners or Steel backed and studded as per requirements. We also have a range of moulded ceramic in rubber with CN backing. The liners can be customized depending on the application.

CCO liners & Ni hard billets

NMC has excellent quality CCO plate and weld wires. The microstructure of Cr7C3 carbide volume fraction is 50% or more, which makes it one of the reliable CCO Liners on the market. The CCO range also comes in Niobium enriched composition to provide additional abrasion resistance.

The CCO plates can be countersunk, counterbored, manufactured to complex profiles, fabricate and roll pipes, wear bands, and sieve plates. TuffClad Pro is perfectly suitable for hard facing applications, which require impact resistance, high abrasion resistance, and the ability to withstand higher temperatures up to 750°C.

Blowbars

We manufacture hammerheads for hammer crushers in Hi-Chrome white iron, Hi-Chrome with ceramic inlays, Mn steel and Mn steel with carbide inserts.